CAD (0)

▾

Cadenas transportadoras de rodillos - Paso de 9.000" a 18.000"

Cadenas transportadoras de rodillos

Las cadenas transportadoras de rodillos de Tsubaki representan las clases de cadenas universales más comunes. Tsubaki se enorgullece de ofrecer una cartera de productos de calidad superior, bien diversificada y fabricada en Sandusky, Ohio.

PASADORES

BUJES

BARRAS LATERALES

RODILLOS

APLICACIONES TÍPICAS

INDUSTRIAS HABITUALES

AUTOMOTRIZ

ALIMENTOS

METALES

FABRICACIÓN GENERAL

AZÚCAR

ESCALERAS MECÁNICAS

PASADORES

- Aleación o acero al carbono de calidad superior.

- Con tratamiento térmico para ofrecer una resistencia y dureza superior.

- Centro templado para ofrecer una resistencia superior al impacto.

- Superficie templada por inducción para ofrecer una mayor resistencia al desgaste.

- Fabricado con precisión para mantener un ajuste de alta interferencia con las barras laterales.

- Evita la rotación de los pasadores y el desgaste posterior de las barras laterales.

BUJES

- Aleación o acero al carbono de calidad superior.

- Con tratamiento térmico para ofrecer una resistencia superior.

- Centro templado para lograr dureza y resistencia a impactos.

- Superficie cementada para ofrecer una resistencia superior al desgaste duradera.

- Maquinados con precisión para mantener las superficies de apoyo lisas y un ajuste de alta interferencia con las barras laterales.

- Las tensiones residuales favorables resisten la fatiga y promueven una vida útil extendida.

BARRAS LATERALES

- Acero al carbono de calidad superior.

- Barras laterales de tratamiento térmico disponibles.

- El acabado de alta calidad del orificio aumenta la resistencia a la fatiga.

- Las tensiones residuales favorables resisten la fatiga y permiten lograr una mayor vida útil.

RODILLOS

- Aleación o acero al carbono de calidad superior.

- Templado para ofrecer una mayor resistencia, dureza y tolerancia a cargas de choque altas.

APLICACIONES TÍPICAS

- Transportadoras

- Elevadores

- Transmisión de potencia

- Transferencia de unidades/materiales

- Transportadoras de ensamblados

INDUSTRIAS HABITUALES

AUTOMOTRIZ

ALIMENTOS

METALES

FABRICACIÓN GENERAL

AZÚCAR

ESCALERAS MECÁNICAS

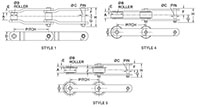

Número de cadena |

Paso |

Estilo de barra lateral |

Ancho interior - A |

Diámetro del rodillo - B |

Diámetro del pasador - C |

Altura de la barra lateral - D |

Espesor de la barra lateral -E |

Cabeza del pasador a CL - F |

Extremo del pasador a CL - G |

Ancho total - H |

Ancho del rodamiento - J |

Resistencia a la rotura promedio |

Carga operativa máx. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B912R | Paso N/D 9.000 in | Estilo de barra lateral N/D 4 | Ancho interior - A N/D 1.50 in | Diámetro del rodillo - B N/D 3.00 in | Diámetro del pasador - C N/D 0.63 in | Altura de la barra lateral - D N/D 2.00 in | Espesor de la barra lateral -E N/D 0.31 in | Cabeza del pasador a CL - F N/D 1.56 in | Extremo del pasador a CL - G N/D 1.85 in | Ancho total - H N/D 3.41 in | Ancho del rodamiento - J N/D | Resistencia a la rotura promedio N/D 36600 lb | Carga operativa máx. N/D 4500 lb |

| 925R | Paso N/D 9.000 in | Estilo de barra lateral N/D 5 | Ancho interior - A N/D 1.69 in | Diámetro del rodillo - B N/D 3.00 in | Diámetro del pasador - C N/D 0.63 in | Altura de la barra lateral - D N/D 2.00 in | Espesor de la barra lateral -E N/D 0.25 in | Cabeza del pasador a CL - F N/D 1.52 in | Extremo del pasador a CL - G N/D 1.80 in | Ancho total - H N/D 3.33 in | Ancho del rodamiento - J N/D 1.13 in | Resistencia a la rotura promedio N/D 45300 lb | Carga operativa máx. N/D 4800 lb |

| B963R | Paso N/D 9.000 in | Estilo de barra lateral N/D 5 | Ancho interior - A N/D 2.00 in | Diámetro del rodillo - B N/D 3.50 in | Diámetro del pasador - C N/D 0.75 in | Altura de la barra lateral - D N/D 2.00 in | Espesor de la barra lateral -E N/D 0.38 in | Cabeza del pasador a CL - F N/D 1.97 in | Extremo del pasador a CL - G N/D 2.34 in | Ancho total - H N/D 4.31 in | Ancho del rodamiento - J N/D 1.25 in | Resistencia a la rotura promedio N/D 53400 lb | Carga operativa máx. N/D 7200 lb |

| D963R | Paso N/D 9.000 in | Estilo de barra lateral N/D 4 | Ancho interior - A N/D 2.00 in | Diámetro del rodillo - B N/D 3.50 in | Diámetro del pasador - C N/D 0.75 in | Altura de la barra lateral - D N/D 2.00 in | Espesor de la barra lateral -E N/D 0.38 in | Cabeza del pasador a CL - F N/D 1.97 in | Extremo del pasador a CL - G N/D 2.34 in | Ancho total - H N/D 4.31 in | Ancho del rodamiento - J N/D | Resistencia a la rotura promedio N/D 53400 lb | Carga operativa máx. N/D 7200 lb |

| 4009 | Paso N/D 9.000 in | Estilo de barra lateral N/D 4 | Ancho interior - A N/D 2.19 in | Diámetro del rodillo - B N/D 3.00 in | Diámetro del pasador - C N/D 0.88 in | Altura de la barra lateral - D N/D 2.50 in | Espesor de la barra lateral -E N/D 0.38 in | Cabeza del pasador a CL - F N/D 2.06 in | Extremo del pasador a CL - G N/D 2.44 in | Ancho total - H N/D 4.50 in | Ancho del rodamiento - J N/D | Resistencia a la rotura promedio N/D 143000 lb | Carga operativa máx. N/D 9000 lb |

| B964R | Paso N/D 9.000 in | Estilo de barra lateral N/D 5 | Ancho interior - A N/D 2.25 in | Diámetro del rodillo - B N/D 4.00 in | Diámetro del pasador - C N/D 0.88 in | Altura de la barra lateral - D N/D 2.50 in | Espesor de la barra lateral -E N/D 0.38 in | Cabeza del pasador a CL - F N/D 2.16 in | Extremo del pasador a CL - G N/D 2.47 in | Ancho total - H N/D 4.63 in | Ancho del rodamiento - J N/D 1.5 in | Resistencia a la rotura promedio N/D 75000 lb | Carga operativa máx. N/D 9200 lb |

| 4004 | Paso N/D 9.000 in | Estilo de barra lateral N/D 4 | Ancho interior - A N/D 2.63 in | Diámetro del rodillo - B N/D 3.00 in | Diámetro del pasador - C N/D 1.00 in | Altura de la barra lateral - D N/D 2.50 in | Espesor de la barra lateral -E N/D 0.50 in | Cabeza del pasador a CL - F N/D 2.59 in | Extremo del pasador a CL - G N/D 3.04 in | Ancho total - H N/D 5.63 in | Ancho del rodamiento - J N/D | Resistencia a la rotura promedio N/D 121000 lb | Carga operativa máx. N/D 12700 lb |

| 4035 | Paso N/D 9.000 in | Estilo de barra lateral N/D 4 | Ancho interior - A N/D 3.19 in | Diámetro del rodillo - B N/D 3.50 in | Diámetro del pasador - C N/D 1.13 in | Altura de la barra lateral - D N/D 3.00 in | Espesor de la barra lateral -E N/D 0.50 in | Cabeza del pasador a CL - F N/D 2.88 in | Extremo del pasador a CL - G N/D 3.31 in | Ancho total - H N/D 6.19 in | Ancho del rodamiento - J N/D | Resistencia a la rotura promedio N/D 131700 lb | Carga operativa máx. N/D 16500 lb |

| 4065 | Paso N/D 9.000 in | Estilo de barra lateral N/D 4 | Ancho interior - A N/D 3.06 in | Diámetro del rodillo - B N/D 4.25 in | Diámetro del pasador - C N/D 1.25 in | Altura de la barra lateral - D N/D 3.50 in | Espesor de la barra lateral -E N/D 0.63 in | Cabeza del pasador a CL - F N/D 3.06 in | Extremo del pasador a CL - G N/D 3.50 in | Ancho total - H N/D 6.56 in | Ancho del rodamiento - J N/D | Resistencia a la rotura promedio N/D 226000 lb | Carga operativa máx. N/D 18900 lb |

| 4037 | Paso N/D 9.000 in | Estilo de barra lateral N/D 4 | Ancho interior - A N/D 3.25 in | Diámetro del rodillo - B N/D 4.50 in | Diámetro del pasador - C N/D 1.50 in | Altura de la barra lateral - D N/D 4.00 in | Espesor de la barra lateral -E N/D 0.63 in | Cabeza del pasador a CL - F N/D 3.28 in | Extremo del pasador a CL - G N/D 3.72 in | Ancho total - H N/D 7.00 in | Ancho del rodamiento - J N/D | Resistencia a la rotura promedio N/D 259000 lb | Carga operativa máx. N/D 23600 lb |

| B1263R | Paso N/D 12.000 in | Estilo de barra lateral N/D 5 | Ancho interior - A N/D 2.00 in | Diámetro del rodillo - B N/D 3.50 in | Diámetro del pasador - C N/D 0.75 in | Altura de la barra lateral - D N/D 2.00 in | Espesor de la barra lateral -E N/D 0.38 in | Cabeza del pasador a CL - F N/D 1.97 in | Extremo del pasador a CL - G N/D 2.34 in | Ancho total - H N/D 4.31 in | Ancho del rodamiento - J N/D 1.25 in | Resistencia a la rotura promedio N/D 53400 lb | Carga operativa máx. N/D 7200 lb |

| D1263R | Paso N/D 12.000 in | Estilo de barra lateral N/D 4 | Ancho interior - A N/D 2.00 in | Diámetro del rodillo - B N/D 3.50 in | Diámetro del pasador - C N/D 0.75 in | Altura de la barra lateral - D N/D 2.00 in | Espesor de la barra lateral -E N/D 0.38 in | Cabeza del pasador a CL - F N/D 1.97 in | Extremo del pasador a CL - G N/D 2.34 in | Ancho total - H N/D 4.31 in | Ancho del rodamiento - J N/D | Resistencia a la rotura promedio N/D 53400 lb | Carga operativa máx. N/D 7200 lb |

| 4251 | Paso N/D 12.000 in | Estilo de barra lateral N/D 1 | Ancho interior - A N/D 1.94 in | Diámetro del rodillo - B N/D 1.75 in | Diámetro del pasador - C N/D 0.88 in | Altura de la barra lateral - D N/D 2.00 in | Espesor de la barra lateral -E N/D 0.50 in | Cabeza del pasador a CL - F N/D 2.25 in | Extremo del pasador a CL - G N/D 2.56 in | Ancho total - H N/D 4.81 in | Ancho del rodamiento - J N/D | Resistencia a la rotura promedio N/D 61200 lb | Carga operativa máx. N/D 8750 lb |

| B1264R | Paso N/D 12.000 in | Estilo de barra lateral N/D 5 | Ancho interior - A N/D 2.25 in | Diámetro del rodillo - B N/D 4.00 in | Diámetro del pasador - C N/D 0.88 in | Altura de la barra lateral - D N/D 2.50 in | Espesor de la barra lateral -E N/D 0.38 in | Cabeza del pasador a CL - F N/D 2.09 in | Extremo del pasador a CL - G N/D 2.47 in | Ancho total - H N/D 4.62 in | Ancho del rodamiento - J N/D 1.5 in | Resistencia a la rotura promedio N/D 70000 lb | Carga operativa máx. N/D 9200 lb |

| B1863R | Paso N/D 18.000 in | Estilo de barra lateral N/D 5 | Ancho interior - A N/D 2.00 in | Diámetro del rodillo - B N/D 3.50 in | Diámetro del pasador - C N/D 0.75 in | Altura de la barra lateral - D N/D 2.00 in | Espesor de la barra lateral -E N/D 0.38 in | Cabeza del pasador a CL - F N/D 1.97 in | Extremo del pasador a CL - G N/D 2.34 in | Ancho total - H N/D 4.31 in | Ancho del rodamiento - J N/D 1.25 in | Resistencia a la rotura promedio N/D 53400 lb | Carga operativa máx. N/D 7200 lb |

| B1864R | Paso N/D 18.000 in | Estilo de barra lateral N/D 5 | Ancho interior - A N/D 2.25 in | Diámetro del rodillo - B N/D 4.00 in | Diámetro del pasador - C N/D 0.88 in | Altura de la barra lateral - D N/D 2.50 in | Espesor de la barra lateral -E N/D 0.38 in | Cabeza del pasador a CL - F N/D 2.16 in | Extremo del pasador a CL - G N/D 2.09 in | Ancho total - H N/D 4.56 in | Ancho del rodamiento - J N/D 1.5 in | Resistencia a la rotura promedio N/D 70000 lb | Carga operativa máx. N/D 9200 lb |