CAD (0)

▾

Cadenas para trituradoras alimentadoras

Cadenas para trituradoras alimentadoras

Tsubaki aprovecha más de un siglo de experiencia en el transporte de agregados y materiales de minería, y se enorgullece de poder ofrecer una cartera líder en el mercado de cadenas para trituradoras/alimentadoras de alta resistencia y calidad superior. Estas ofertas de productos están diseñadas exclusivamente para alcanzar una máxima durabilidad,

previsibilidad y confiabilidad en las aplicaciones de alimentadoras más exigentes.

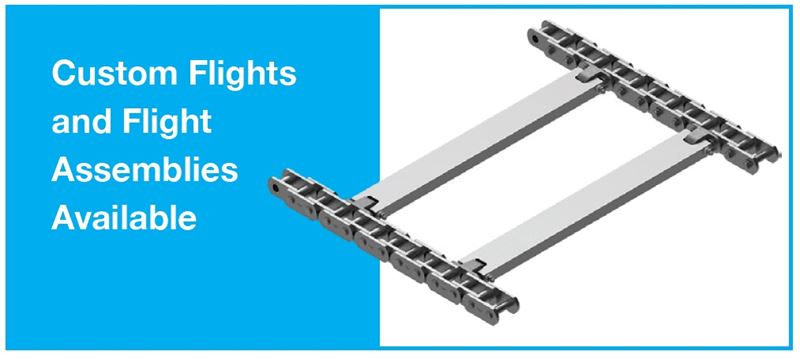

Rastras personalizadas y ensamblados de rastras disponibles

</>

</>

PASADORES

BUJES

BARRAS LATERALES

APLICACIONES TÍPICAS

INDUSTRIAS HABITUALES

MINERALES INDUSTRIALES

MINERÍA

CEMENTO

FERTILIZANTES

GAS Y PETRÓLEO

GENERADOR DE ENERGÍA

Rastras personalizadas y ensamblados de rastras disponibles

</>

</>

PASADORES

- Acero de aleación de grado superior.

- Con tratamiento térmico para ofrecer una resistencia y dureza superior.

- Centro templado para ofrecer una resistencia superior al impacto.

- Superficie templada por inducción para ofrecer una mayor resistencia al desgaste.

- Fabricado con precisión para mantener un ajuste de alta interferencia con las barras laterales.

- Evita la rotación de los pasadores y el desgaste posterior de las barras laterales.

BUJES

- Acero de aleación de calidad superior.

- Con tratamiento térmico para ofrecer una resistencia superior.

- Centro templado para ofrecer dureza y resistencia al impacto.

- Superficie cementada para ofrecer una resistencia al desgaste superior o extendida.

- Fabricado con precisión para mantener un ajuste de alta interferencia con las barras laterales.

- Las tensiones residuales favorables resisten la fatiga y permiten lograr una mayor vida útil.

BARRAS LATERALES

- Aleación o acero al carbono de calidad superior.

- Con proceso de cementado para ofrecer mayor solidez, dureza y resistencia a la fatiga.

- Los bordes de la barra lateral templada por inducción también están disponibles para ofrecer una mayor resistencia al desgaste.

- Los procesos de fabricación patentados garantizan una calidad uniforme en los orificios y un control preciso del paso.

- El acabado de alta calidad del orificio aumenta la resistencia a la fatiga.

APLICACIONES TÍPICAS

- Alimentador/trituradores subterráneos

- Alimentadoras/trituradoras en la superficie

- Alimentadores de estilo colectora de excavadora

- Sistemas de rastras sumergidas

INDUSTRIAS HABITUALES

MINERALES INDUSTRIALES

MINERÍA

CEMENTO

FERTILIZANTES

GAS Y PETRÓLEO

GENERADOR DE ENERGÍA

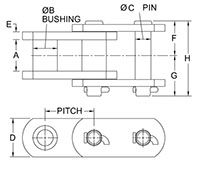

N.º de artículo |

Paso |

Ancho interior - A |

Diámetro del buje - B |

Diámetro del pasador - C |

Altura de la barra lateral - D |

Espesor de la barra lateral -E |

Cabeza del pasador a CL - F |

Extremo del pasador a CL - G |

Ancho total - H |

Resistencia a la rotura promedio |

Carga operativa máx. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| FB3067 | Paso N/D 3.067 in | Ancho interior - A N/D 1.56 in | Diámetro del buje - B N/D 1.50 in | Diámetro del pasador - C N/D 0.75 in | Altura de la barra lateral - D N/D 2.25 in | Espesor de la barra lateral -E N/D 0.38 in | Cabeza del pasador a CL - F N/D 1.72 in | Extremo del pasador a CL - G N/D 2.13 in | Ancho total - H N/D 3.84 in | Resistencia a la rotura promedio N/D 141000 lb | Carga operativa máx. N/D 7600 lb |

| FB3075 | Paso N/D 3.075 in | Ancho interior - A N/D 1.31 in | Diámetro del buje - B N/D 1.25 in | Diámetro del pasador - C N/D 0.68 in | Altura de la barra lateral - D N/D 1.50 in | Espesor de la barra lateral -E N/D 0.38 in | Cabeza del pasador a CL - F N/D 1.63 in | Extremo del pasador a CL - G N/D 1.88 in | Ancho total - H N/D 3.50 in | Resistencia a la rotura promedio N/D 69000 lb | Carga operativa máx. N/D 4900 lb |

| FB3035 | Paso N/D 3.000 in3.500 in | Ancho interior - A N/D 1.88 in | Diámetro del buje - B N/D 1.50 in | Diámetro del pasador - C N/D 0.99 in | Altura de la barra lateral - D N/D 2.50 in | Espesor de la barra lateral -E N/D 0.56 in | Cabeza del pasador a CL - F N/D 2.28 in | Extremo del pasador a CL - G N/D 2.72 in | Ancho total - H N/D 5.00 in | Resistencia a la rotura promedio N/D 160000 lb | Carga operativa máx. N/D 10400 lb |

| FB3040 | Paso N/D 3.000 in4.000 in | Ancho interior - A N/D 1.88 in | Diámetro del buje - B N/D 1.50 in | Diámetro del pasador - C N/D 0.99 in | Altura de la barra lateral - D N/D 2.50 in | Espesor de la barra lateral -E N/D 0.56 in | Cabeza del pasador a CL - F N/D 2.28 in | Extremo del pasador a CL - G N/D 2.72 in | Ancho total - H N/D 5.00 in | Resistencia a la rotura promedio N/D 160000 lb | Carga operativa máx. N/D 10400 lb |

| FB3500 | Paso N/D 3.500 in | Ancho interior - A N/D 2.25 in | Diámetro del buje - B N/D 1.75 in | Diámetro del pasador - C N/D 1.13 in | Altura de la barra lateral - D N/D 2.75 in | Espesor de la barra lateral -E N/D 0.56 in | Cabeza del pasador a CL - F N/D 2.47 in | Extremo del pasador a CL - G N/D 2.91 in | Ancho total - H N/D 5.38 in | Resistencia a la rotura promedio N/D 164000 lb | Carga operativa máx. N/D 13300 lb |

| FB3750 | Paso N/D 3.750 in | Ancho interior - A N/D 2.25 in | Diámetro del buje - B N/D 1.75 in | Diámetro del pasador - C N/D 1.19 in | Altura de la barra lateral - D N/D 2.75 in | Espesor de la barra lateral -E N/D 0.56 in | Cabeza del pasador a CL - F N/D 2.53 in | Extremo del pasador a CL - G N/D 2.84 in | Ancho total - H N/D 5.37 in | Resistencia a la rotura promedio N/D 160000 lb | Carga operativa máx. N/D 14000 lb |

| FB4000 | Paso N/D 4.000 in | Ancho interior - A N/D 1.94 in | Diámetro del buje - B N/D 1.75 in | Diámetro del pasador - C N/D 0.94 in | Altura de la barra lateral - D N/D 2.38 in | Espesor de la barra lateral -E N/D 0.56 in | Cabeza del pasador a CL - F N/D 2.45 in | Extremo del pasador a CL - G N/D 2.75 in | Ancho total - H N/D 5.20 in | Resistencia a la rotura promedio N/D 140000 lb | Carga operativa máx. N/D 10000 lb |

| FB4500 | Paso N/D 4.500 in | Ancho interior - A N/D 2.75 in | Diámetro del buje - B N/D 2.38 in | Diámetro del pasador - C N/D 1.37 in | Altura de la barra lateral - D N/D 3.50 in | Espesor de la barra lateral -E N/D 0.63 in | Cabeza del pasador a CL - F N/D 2.91 in | Extremo del pasador a CL - G N/D 3.34 in | Ancho total - H N/D 6.25 in | Resistencia a la rotura promedio N/D 283500 lb | Carga operativa máx. N/D 19200 lb |

| FB5500 | Paso N/D 5.500 in | Ancho interior - A N/D 2.75 in | Diámetro del buje - B N/D 2.50 in | Diámetro del pasador - C N/D 1.46 in | Altura de la barra lateral - D N/D 4.00 in | Espesor de la barra lateral -E N/D 0.75 in | Cabeza del pasador a CL - F N/D 3.19 in | Extremo del pasador a CL - G N/D 3.63 in | Ancho total - H N/D 6.81 in | Resistencia a la rotura promedio N/D 315000 lb | Carga operativa máx. N/D 21700 lb |

| FB6000 | Paso N/D 6.000 in | Ancho interior - A N/D 3.63 in | Diámetro del buje - B N/D 2.75 in | Diámetro del pasador - C N/D 1.75 in | Altura de la barra lateral - D N/D 4.50 in | Espesor de la barra lateral -E N/D 0.88 in | Cabeza del pasador a CL - F N/D 3.84 in | Extremo del pasador a CL - G N/D 4.17 in | Ancho total - H N/D 8.02 in | Resistencia a la rotura promedio N/D 480000 lb | Carga operativa máx. N/D 33000 lb |