MultiCAD Download (0)

▾

Drive Chain - Straight Sidebar

Drive Chains

Tsubaki is proud to offer a market leading portfolio of Engineering Class Drive Chains. This unique and encompassing collection of premium designs has been continuously improved and perfected over the last century.

Manufactured in Sandusky, Ohio since 1917, this cornerstone product is widely recognized around the world for its superior quality and workmanship. When it comes to efficient power transfer, Tsubaki Drive Chain is second to none.

PINS

ASPHALT

MINING

CEMENT

INDUSTRIALS MINERALS

OIL & GAS

GENERAL MANUFACTURING

FORESTRY, PULP, PAPER

Manufactured in Sandusky, Ohio since 1917, this cornerstone product is widely recognized around the world for its superior quality and workmanship. When it comes to efficient power transfer, Tsubaki Drive Chain is second to none.

PINS

- Premium alloy steel.

- Heat treated for superior strength and toughness.

- Core – Through hardened for superior impact resistance.

- Surface – Induction hardened for extended wear resistance.

- Precision manufactured to maintain high interference fit with sidebars.

- Prevents pin rotation and subsequent sidebar wear.

- Premium alloy steel.

- Heat treated for superior strength.

- Surface – Case hardened for ultimate/extended wear resistance.

- Precision manufactured to maintain smooth bearing surfaces and high interference fit with sidebars.

- Favorable residual stresses resist fatigue and allow for extended life.

- Premium alloy steel.

- Heat treated for superior strength, toughness and fatigue resistance.

- Proprietary manufacturing processes ensure consistent hole quality and precise pitch control.

- Premium alloy steel.

- Through hardened for superior strength, toughness and the ability to withstand high shock loads.

- Mechanical Drives

- Drum Drives

- Draw Bench

- Crawler Crane Drives

ASPHALT

MINING

CEMENT

INDUSTRIALS MINERALS

OIL & GAS

GENERAL MANUFACTURING

FORESTRY, PULP, PAPER

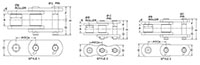

Tsubaki Part Number |

Chain Number |

Sidebar Style |

Pitch |

Inside Width - A |

Roller Diameter - B |

Pin Diameter - C |

Sidebar Height - D |

Sidebar Thickness - E |

Pin Head to CL - F |

Pin End to CL -G |

Overall Width - H |

Average Ultimate Strength |

Max Working Load |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8356 | Chain Number N/A US64S | Sidebar Style N/A 2 | Pitch N/A 2.500 in | Inside Width - A N/A 1.50 in | Roller Diameter - B N/A 1.56 in | Pin Diameter - C N/A 0.88 in | Sidebar Height - D N/A 2.37 in | Sidebar Thickness - E N/A 0.38 in | Pin Head to CL - F N/A 1.69 in | Pin End to CL -G N/A 2.00 in | Overall Width - H N/A 3.69 in | Average Ultimate Strength N/A 122000 lb | Max Working Load N/A 6900 lb |

| 11808 | Chain Number N/A 344SXX | Sidebar Style N/A 1 | Pitch N/A 3.000 in | Inside Width - A N/A 1.94 in | Roller Diameter - B N/A 1.78 in | Pin Diameter - C N/A 0.94 in | Sidebar Height - D N/A 2.38 in | Sidebar Thickness - E N/A 0.56 in | Pin Head to CL - F N/A 2.38 in | Pin End to CL -G N/A 2.75 in | Overall Width - H N/A 5.13 in | Average Ultimate Strength N/A 181500 lb | Max Working Load N/A 10000 lb |

| 14139 | Chain Number N/A US4031 | Sidebar Style N/A 1 | Pitch N/A 4.000 in | Inside Width - A N/A 2.75 in | Roller Diameter - B N/A 2.50 in | Pin Diameter - C N/A 1.25 in | Sidebar Height - D N/A 3.50 in | Sidebar Thickness - E N/A 0.63 in | Pin Head to CL - F N/A 2.91 in | Pin End to CL -G N/A 3.36 in | Overall Width - H N/A 6.28 in | Average Ultimate Strength N/A 321000 lb | Max Working Load N/A 17500 lb |

| 21400 | Chain Number N/A US1353 | Sidebar Style N/A 3 | Pitch N/A 4.090 in | Inside Width - A N/A 2.25 in | Roller Diameter - B N/A 2.63 in | Pin Diameter - C N/A 1.31 in | Sidebar Height - D N/A 3.50 in | Sidebar Thickness - E N/A 0.63 in | Pin Head to CL - F N/A 2.66 in | Pin End to CL -G N/A 3.09 in | Overall Width - H N/A 5.75 in | Average Ultimate Strength N/A 305500 lb | Max Working Load N/A 16000 lb |

| 22874 | Chain Number N/A US5021 | Sidebar Style N/A 3 | Pitch N/A 5.000 in | Inside Width - A N/A 2.25 in | Roller Diameter - B N/A 2.63 in | Pin Diameter - C N/A 1.31 in | Sidebar Height - D N/A 3.50 in | Sidebar Thickness - E N/A 0.63 in | Pin Head to CL - F N/A 2.66 in | Pin End to CL -G N/A 3.09 in | Overall Width - H N/A 5.75 in | Average Ultimate Strength N/A 276000 lb | Max Working Load N/A 16000 lb |

| 13423 | Chain Number N/A US5042 | Sidebar Style N/A 1 | Pitch N/A 5.000 in | Inside Width - A N/A 3.00 in | Roller Diameter - B N/A 3.00 in | Pin Diameter - C N/A 1.50 in | Sidebar Height - D N/A 4.00 in | Sidebar Thickness - E N/A 0.75 in | Pin Head to CL - F N/A 3.41 in | Pin End to CL -G N/A 3.84 in | Overall Width - H N/A 7.25 in | Average Ultimate Strength N/A 440000 lb | Max Working Load N/A 23600 lb |

| 19711 | Chain Number N/A US6566 | Sidebar Style N/A 1 | Pitch N/A 6.500 in | Inside Width - A N/A 3.25 in | Roller Diameter - B N/A 3.50 in | Pin Diameter - C N/A 1.75 in | Sidebar Height - D N/A 6.00 in | Sidebar Thickness - E N/A 0.88 in | Pin Head to CL - F N/A 3.95 in | Pin End to CL -G N/A 4.23 in | Overall Width - H N/A 8.19 in | Average Ultimate Strength N/A 572000 lb | Max Working Load N/A 30600 lb |

| 24853 | Chain Number N/A US6065 | Sidebar Style N/A 3 | Pitch N/A 6.500 in | Inside Width - A N/A 3.25 in | Roller Diameter - B N/A 3.75 in | Pin Diameter - C N/A 1.75 in | Sidebar Height - D N/A 6.00 in | Sidebar Thickness - E N/A 0.88 in | Pin Head to CL - F N/A 3.95 in | Pin End to CL -G N/A 4.23 in | Overall Width - H N/A 8.19 in | Average Ultimate Strength N/A 572300 lb | Max Working Load N/A 30600 lb |

| 24531 | Chain Number N/A US6550 | Sidebar Style N/A 1 | Pitch N/A 6.500 in | Inside Width - A N/A 3.50 in | Roller Diameter - B N/A 3.50 in | Pin Diameter - C N/A 2.01 in | Sidebar Height - D N/A 5.00 in | Sidebar Thickness - E N/A 0.63 in | Pin Head to CL - F N/A 3.47 in | Pin End to CL -G N/A 3.97 in | Overall Width - H N/A 7.44 in | Average Ultimate Strength N/A 474000 lb | Max Working Load N/A 35000 lb |

| 17496 | Chain Number N/A US7080 | Sidebar Style N/A 1 | Pitch N/A 7.000 in | Inside Width - A N/A 3.25 in | Roller Diameter - B N/A 4.50 in | Pin Diameter - C N/A 2.13 in | Sidebar Height - D N/A 6.00 in | Sidebar Thickness - E N/A 0.88 in | Pin Head to CL - F N/A 3.81 in | Pin End to CL -G N/A 4.19 in | Overall Width - H N/A 8.00 in | Average Ultimate Strength N/A 753500 lb | Max Working Load N/A 37300 lb |