CAD (0)

▾

Para enviar suas informações para a Tsubaki, pressione este botão

Tsubaki’s new BS-F Series backstops are designed for simple, drop-in installation to all major competitive external, low-speed backstop products. These backstops use a

unique labyrinth seal design for maximum life with minimal maintenance.

With Tsubaki’s innovative design features, our backstops ensure efficient and dependable operation in the harshest environments.

TYPICAL APPLICATIONS

COMMON INDUSTRIES

MINING

POWER GENERATING PLANTS

CEMENT

PORTS

INNOVATIVE FEATURES:

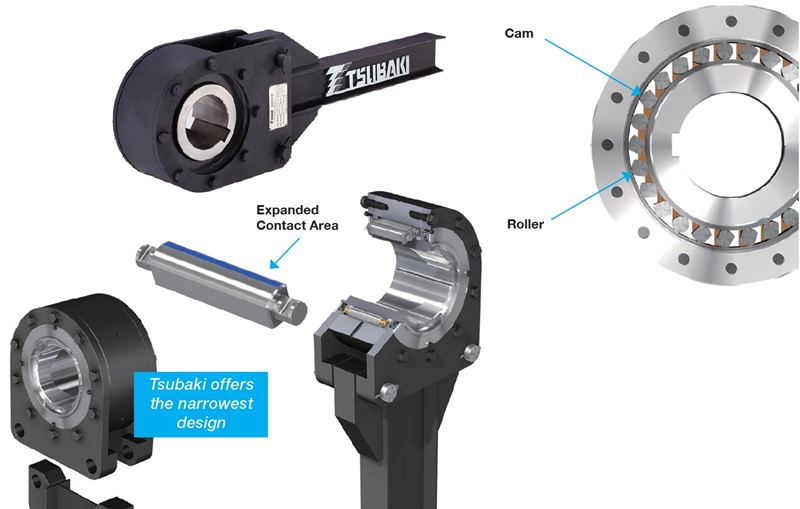

NON-ROLLOVER CAM

SPECIAL LABYRINTH SEAL

Superior Performance in the Harshest Environments

GREASE LUBRICATION

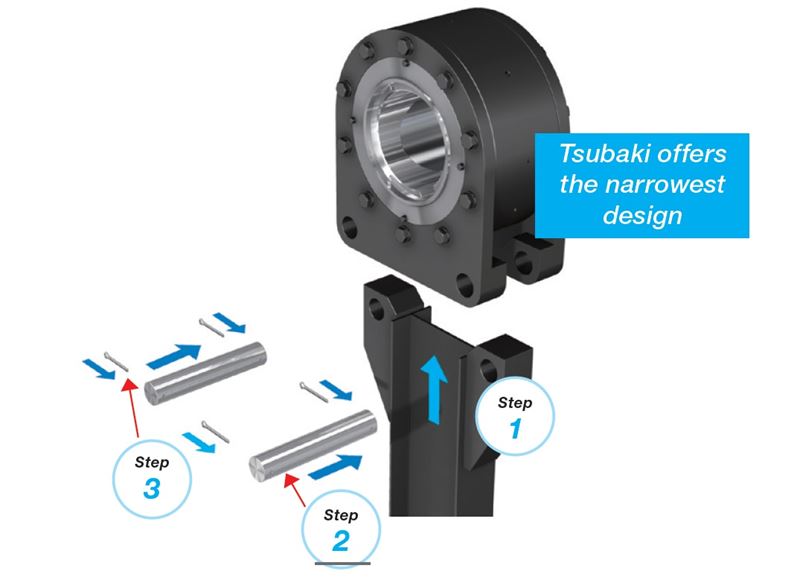

DROP IN DESIGN

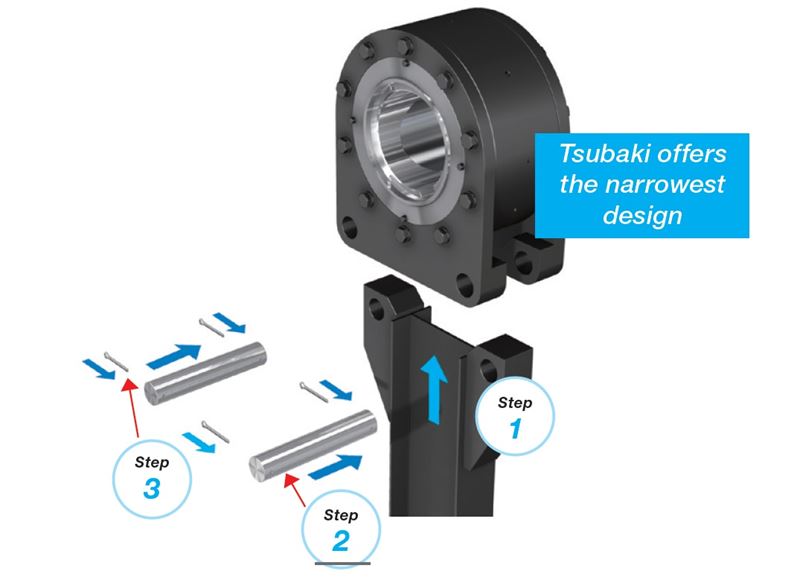

3 STEP

EASY CONNECTION

Step 1: Insert I-beam torque arm into clutch

Step 2: Insert lock pins through flange plate and secure torque arm

Step 3: Insert retaining pins into lock pins

TYPICAL APPLICATIONS

- Mining (Coal, Copper, Potash) - used in inclined conveyors and bucket elevators for transporting raw materials.

- Power Generating Plants - used in inclined conveyors to transfer coal from the stockpile to the boiler rooms.

- Cement Plants - used in bucket elevators and inclined conveyors for moving limestone and clay to crushers and silos.

COMMON INDUSTRIES

MINING

POWER GENERATING PLANTS

CEMENT

PORTS

INNOVATIVE FEATURES:

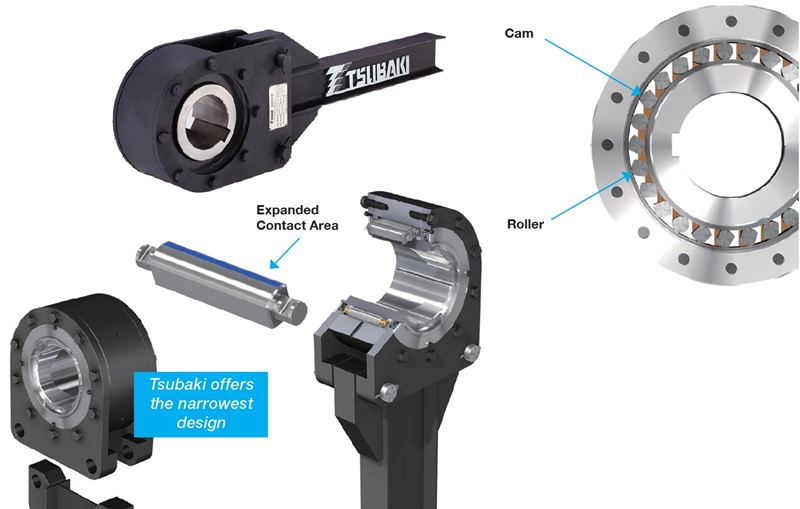

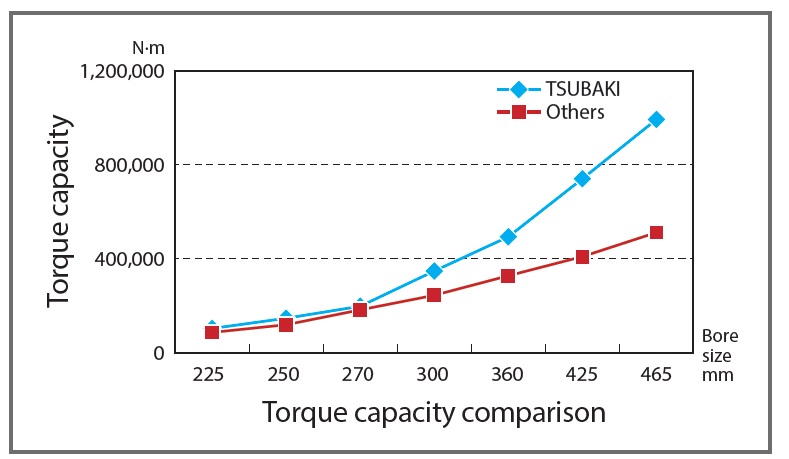

NON-ROLLOVER CAM

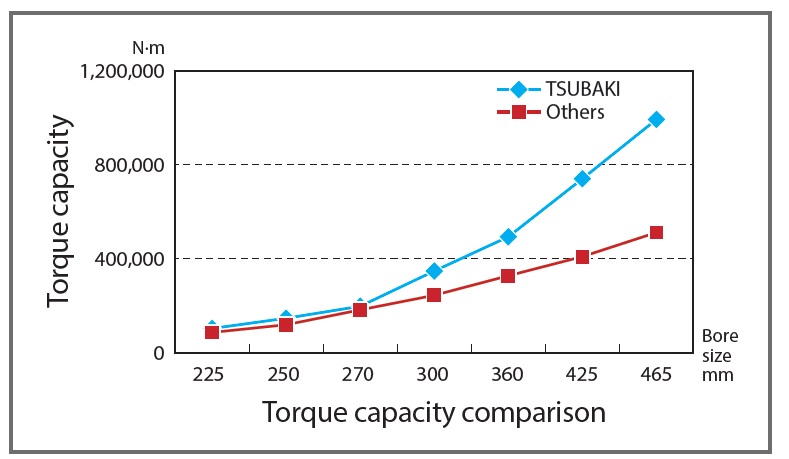

- Provides higher torque ratings than the leading competitors due to the larger profile and greater contact area.

- Improves performance and prevents costly and potentially dangerous rollover.

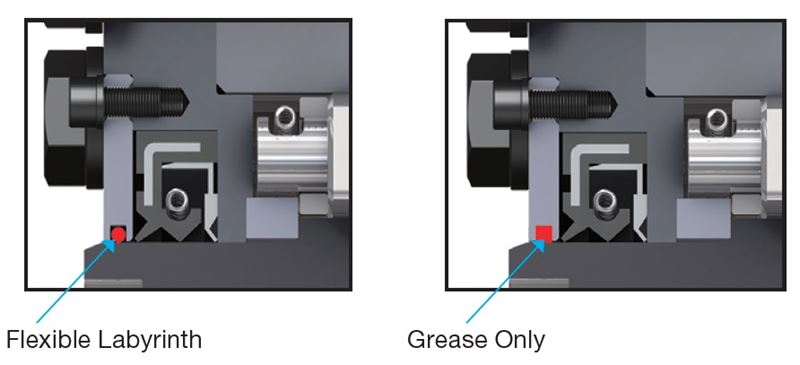

SPECIAL LABYRINTH SEAL

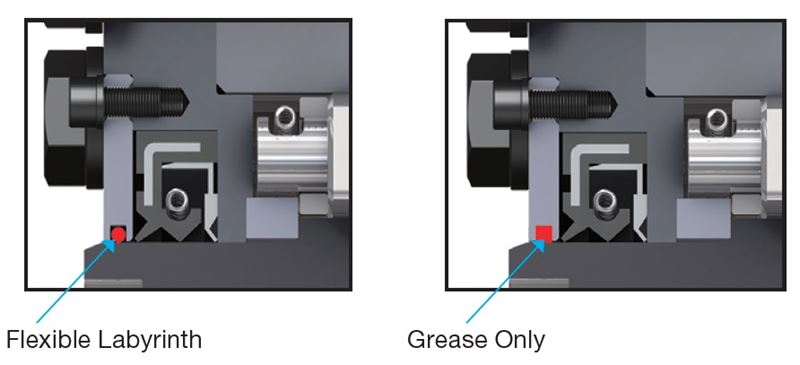

- New seal design prevents the ingress of dust and other contaminants typically found in mining and cement plants, which extends the life of the lubricant.

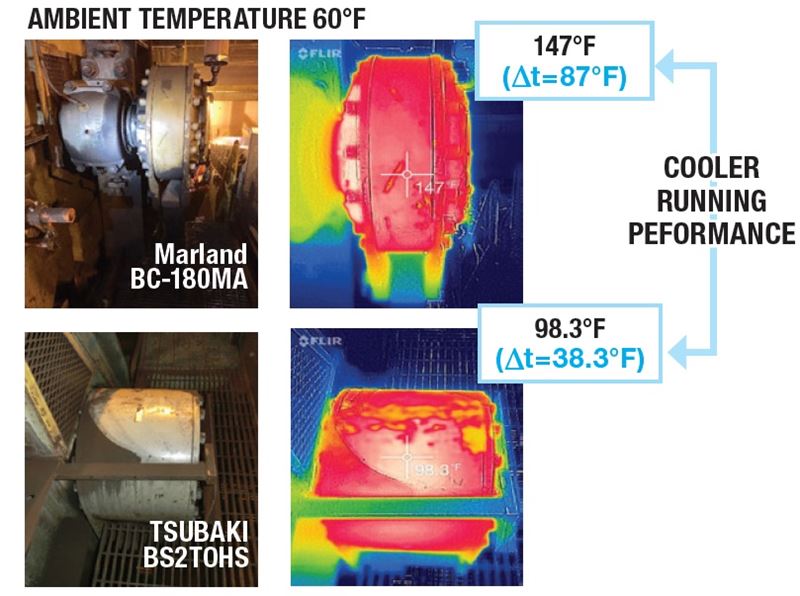

- Minimizes heat generation and provides trouble-free service with minimal scheduled maintenance.

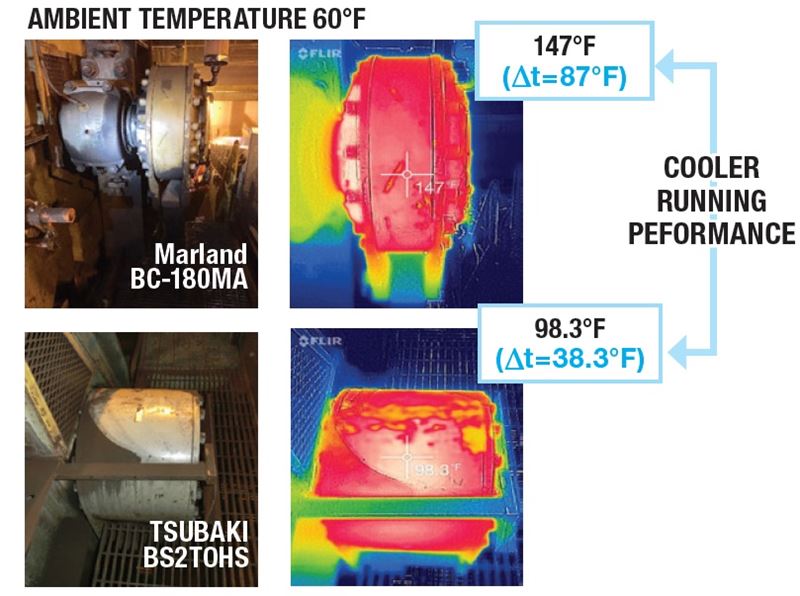

Superior Performance in the Harshest Environments

GREASE LUBRICATION

- Offers synthetic grease lubrication in a sealed backstop design.

- Breather element is eliminated.

- No need to monitor oil levels, refill the backstop or worry about moisture in the lubricant.

- Provides trouble-free performance with minimized maintenance requirements.

DROP IN DESIGN

- Tsubaki offers the narrowest backstop with an I-beam torque arm.

- Quick and easy field replacement. Drop in compatible with most competitive products.

3 STEP

EASY CONNECTION

Step 1: Insert I-beam torque arm into clutch

Step 2: Insert lock pins through flange plate and secure torque arm

Step 3: Insert retaining pins into lock pins

Unidade de medida

Especificações

Intervalo de orifício – máx. |

N/A 11.810 pol.300.00 mm |

Intervalo de orifício – mín. |

N/A 9.050 pol.230.00 mm |

Torque Capacity |

N/A 254000 lb·pé345000 N·m |

Velocidade máxima de avanço do anel interno |

N/A 115 rpm |

Torque de arrasto |

N/A 79.600 lb·pé108.00 N·m |

A – Largura do contrarrecuo |

N/A 10.940 pol.278.00 mm |

B – Comprimento total |

N/A 30.710 pol.780.00 mm |

C – Largura interna |

N/A 10.750 pol.273.00 mm |

D – Linha central do contrarrecuo até a borda do flange |

N/A 19.290 pol.490.00 mm |

E – Diâmetro interno do escareamento |

N/A 16.930 pol.430.00 mm |

F – Largura total do anel interno |

N/A 11.260 pol.286.00 mm |

G – Profundidade do escareamento |

N/A 0.260 pol.6.50 mm |

H – Largura total do contrarrecuo |

N/A 12.600 pol.320.00 mm |

J – Distância da linha central do contrarrecuo à borda da viga I |

N/A 94.020 pol.2388.00 mm |

K – Altura do braço de torque |

N/A 15.000 pol.381.00 mm |

L – Largura do braço de torque |

N/A 5.630 pol.143.00 mm |

Quantidade de graxa |

N/A 3.960 lb1.800 kg |

Peso – com braço de torque – orifício mínimo |

N/A 2860.000 lb1300.000 kg |

Peso – com braço de torque – orifício máximo |

N/A 2706.000 lb1230.000 kg |

Peso – sem braço de torque – orifício mínimo |

N/A 2310.000 lb1050.000 kg |

Peso – sem braço de torque – máx. Orifício |

N/A 2140.600 lb973.000 kg |