ANSI Single Pitch Sprockets

Key Features

- Due to the small pitch of these chains, the drive design is smaller.

- Usually sprockets with a large number of teeth are used. The chain speed does not vary significantly as the chain engages with sprockets. With less impact, there is also less noise generated as a result of the impact between the roller and sprocket tooth.

- These chains may be used for high speed conveyor applications.

- A wide variety of standard and special attachments are available for this chain series.

Tsubaki ANSI Single Pitch Sprockets come in a variety of sizes and specs. Find the right product for your operational needs below, and request a quote today.

About Tsubaki Sprockets

Keep your system on the cutting edge with U.S. Tsubaki sprockets, and discover the difference quality makes. U.S. Tsubaki sprockets are manufactured from top-grade, heat treated steel to withstand heavy shock loading, resist abrasion, and provide long service life. Alloy and stainless steel sprockets are also available for extra corrosion resistance and food-grade applications.

/Asset/H60B25-1.jpg

Tsubaki Double Pitch Sprockets

U.S. Tsubaki offers premium double pitch sprockets that help optimize your operations. Learn more about the benefits of our double pitch sprockets and see our product options.

Double Pitch Sprockets

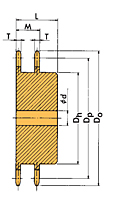

Tsubaki Double Pitch Sprockets resemble single pitch sprockets, but the chain only engages every other tooth. This means that double-pitch sprockets can have the same number of teeth as a single pitch sprocket but only half teeth will engage the chain. The primary difference is that double pitch sprockets are cut with a special pitch diameter for optimum engagement. For ASME roller chains, the sprockets are identical for single and double pitch chains if they have 32 or more teeth.

Find the right double pitch sprocket for your operational needs by exploring our product options.

Choose Tsubaki for High-Quality Sprockets

Sprockets transmit reliable mechanical force using simple, yet highly essential mechanisms; therefore, it is important to choose the right parts to ensure long life for your critical system, considering loads and manufacturing conditions. Tsubaki has been creating high-quality roller chains and conveyance parts for over 100 years, and we have an extensive line of standard and specialized sprockets. Contact us to find the right sprockets for your systems or equipment today.

/Asset/double_pitch_spkt.jpg

Steel Split Sprockets

(6) Steel Split HubLength through bore can be determined by adding plate thickness to hub length.

U.S. Tsubaki Steel Split Sprocket Hubs are designed to integrate with "A" style sprockets. The primary advantage in utilizing Steel Split Hubs is to allow for ease of installation and removal of a given sprocket for applications that are limited in space, or require more frequent maintenance. When selecting a Steel Split Sprocket Hub, please reference the Sprocket Size for Instant Hub chart to determine the minimum pitch and tooth count for a given Steel Split Hub. /Asset/Steel_Split.jpg

Tsubaki Idler Sprockets

U.S. Tsubaki offers a variety of Idler Sprockets that are made to optimize your operations. Learn more about our Free Flow Chains and view our product options to find the right fit for your application.

Idler Sprockets

U.S. Tsubaki offers two types of Idler Sprockets, Chain Tensioners and Ball Bearing Idler Sprockets. Learn more about each type to determine the right fit for your operational needs and request a quote today.

About Tsubaki Sprockets

Keep your system on the cutting edge with U.S. Tsubaki sprockets, and discover the difference quality makes. U.S. Tsubaki sprockets are manufactured from top-grade, heat treated steel to withstand heavy shock loading, resist abrasion, and provide long service life. Alloy and stainless steel sprockets are also available for extra corrosion resistance and food-grade applications.

/Asset/e118.jpg

Sprockets for Double Plus® Chain

(5) Sprockets for Double Plus® chain(For DOUBLE PLUS "VR", "VRP", "VR-SC", & "VRP-SC") /Asset/a1900.jpg