-

Engineering Class Sprockets

engineering-class-sprockets_

-

Engineering Class Sprockets

ENGINEERING CLASS SPROCKETS FROM TSUBAKI®

- Tsubaki maintains a wide array of sprocket options and can offer premium fabricated sprockets and traction rims for most Engineering Class applications.

- Tsubaki sprockets are designed specifically based on the mating chain to assure proper dynamic interaction/articulation.

- High Carbon, Alloy or Stainless materials are available.

- A keyway and 2 set screws is standard, other locking options available on request.

- All Tsubaki Engineering Class sprockets/traction rims are uniquely heat treated based on specific, proprietary schedules to ensure long and reliable service life.

- Lightening holes, utilized to reduce weight and allow for efficient/safe handling are available for most designs.

- Leverage the following data sheets to accurately document your sprocket for a quotation or call 1-800-323-7790 to discuss your project in detail with a Tsubaki Sprocket Specialist.

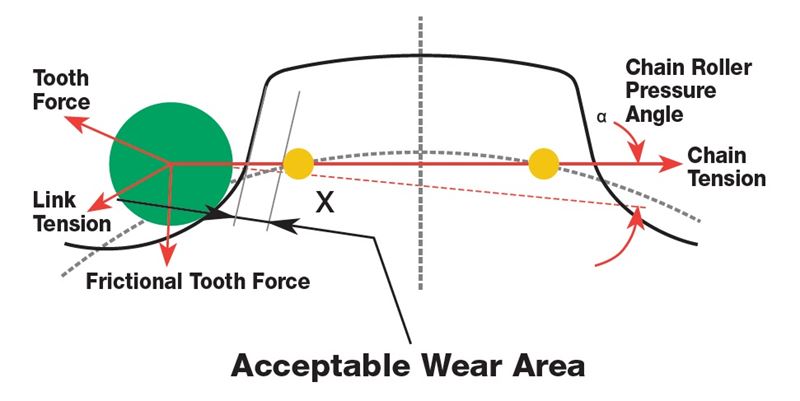

Smart Tooth® Sprocket Technology

Tsubaki’s Smart Tooth®sprockets with patented Wear Indicator Technology offer the ability to easily and proactively identify and schedule maintenance before a critical component failure. This innovative design not only allows for proactive sprocket wear identification, it also mitigates the risk of worn sprockets permanently damaging the mating chain. This patented technology is available on most Engineering Class Sprockets.

Acceptable Wear Area

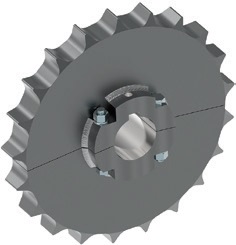

Sprocket Construction Types / Styles

Solid- Solid plate, welded to solid hub.

- A basic, economic construction.

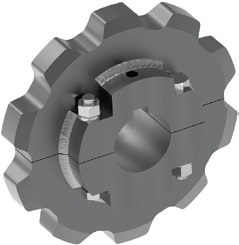

Split- Split plate, split hub.

- A basic construction that allows for easier installation – can remove without removing shaft.

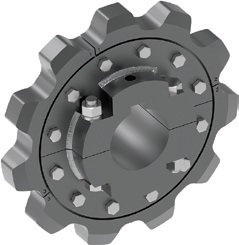

Segmented- Solid plate welded to hub with bolt on segments.

- An innovative construction that allows for easy segment replacement—can remove without removing shaft or hub body.

Segmented / Split- A split plate/hub with bolt on segments.

- Ultimate flexibility – Segment or hub body can be easily serviced/replaced without removing shaft.

Hunting Tooth- A unique construction that allows for extended service life.

- Hunting tooth sprockets have an odd number of teeth and are half the pitch of the mating chain. Every time the sprocket makes a revolution, the chain engages with one set of teeth, ahead of the previously engaged set. Hence, each sprocket tooth only sees engagement every other rotation.

Double Duty- An innovative construction that allow for extended service life.

- Double Duty sprockets are double cut and have an even number of teeth. Utilizing strategic, manual indexing, this design can provide extended service life, somewhat similar to a hunting design for an even tooth setup.

Chain Saver Sprockets- A unique design that incorporates a special flanged rim on either side of the sprocket body. The chain sidebars rest on the flange as the chain wraps around the sprocket. This configuration keeps the chain on true center and distributes the load over a greater contact area, thus reducing the rate of wear.

Traction Rim / Wheel- Essentially a sprocket without teeth.

- Available as a solid, segmented or a segmented/split design.

- Ideal for single strand bucket elevators and/or abrasive conveyor applications.

- Coefficient of friction must be great enough to allow the wheel to drive.

- Key Benefit – Allows the chain to slip in an overload or obstructed condition.

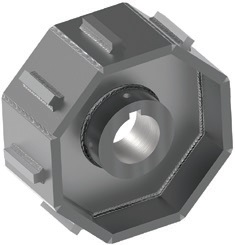

Octagonal Wheel- Utilized with Heavy Duty Hard Faced Drag Chains. (See Page 243)

- Octagon shape allows the dynamic forces to be transferred directly between chain sidebars and the flats of the octagon. This eliminates the traditional sprocket tooth/ chain bushing wear point.

- Guide lugs are typical and keep the chain on center.

- Hardfacing available for extreme conditions.

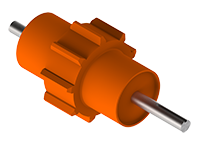

Full-Face Drum Sprocket- Highly respected design regularly utilized with both Welded Mill and Welded Drag chain. (See Pages 195 and 234)

- Full-Face design offers an increased surface area which reduces contact pressures and in turn offers solid wear performance.

- Available in single and multi-strand configurations.

A-Plate Drum Sprocket- Classic, traditional style utilized with both Welded Mill and Welded Drag chain. (See Pages 195 and 234)

- Can handle misalignment quite well.

- Open design allows for bulk material pass through.

- Available in single and multi-strand configurations.